Treatment of industrial waste water

Wastewater technology based on the evaporation of wastewater

With Envotherm’s combination of evaporation and absorption technology, you are assured of efficient wastewater treatment with the lowest energy consumption on the market.

Evaporation through atmospheric pressure

Plug-and-play solution

20-45 kWh/m3

Capacity from 750 m3 to 14.000 m3 per year

Self-cleaning

Fully automated

Can recycle up to 99% wastewater

Zero Liquid Discharge

What is ZLD?

ZLD stands for Zero Liquid Discharge and is a term for a wastewater technology in which all contaminants are separated from the water and no water is wasted. Instead, the water can be used again and again.

By using a ZLD system, you optimise your wastewater treatment and save resources.

There are many different advantages to using a ZLD technology, the most important of which are:

Reduced waste

With Envotherm’s E-MVR technology, you reduce your wastewater volume by 95-99%.

Reduction of CO2 emissions

The process of incinerating wastewater is extremely CO2-intensive. With the reduced amount of wastewater, significantly less CO2 is generated from incineration. In addition, transport to and from incinerators is also minimised, and transport-related CO2 emissions will therefore also be minimised.

Recycling of resources

In some cases, resources separated from the water can be recycled. This is relevant, for example, if your business handles precious metals such as gold or silver.

Wastewater Technology

with minimal energy consumption

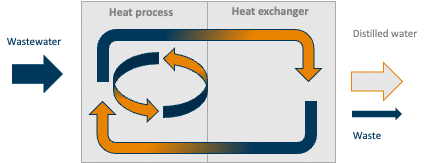

Heat exchanger

By reusing the outgoing steam to heat the incoming wastewater, an Envotherm plant requires 66% less energy than an equivalent plant from competing technologies.

Evaporation process

With evaporation technology from Envotherm, you get a completely pure distillate that can be reused as soft water in your production, or discharged directly to sewer.

E-MVR

How can E-MVR use so much less energy?

E-MVR, Envotherm’s patented wastewater treatment technology, stands for Envotherm Mechanical Vapor Recompression, and is an evaporation technology for treating industrial wastewater.

E-MVR is both the name of our technology and the process by which the energy from the steam of the outgoing distillate is recycled to heat incoming wastewater.

Reuse of heat

Compared to e.g. vacuum evaporation, where wastewater is fed into a vacuum chamber in batches, wastewater is fed continuously into the evaporation chamber with E-MVR. Therefore, when using vacuum evaporation, you need energy to start the pump/compressor each time a new batch is fed into the chamber. This energy cannot be reused, while the excess heat from the outgoing batch is not sufficient to have a significant effect on the heating of the next batch. Therefore, vacuum evaporation has a high energy loss.

When using E-MVR, the compressor runs continuously and the heat never leaves the heating process. As the evaporation chamber is connected to the preheater, this means that only a minimal amount of energy needs to be added to maintain the evaporation process in the evaporator.

The energy efficiency of E-MVR technology means our wastewater plants can run at full power, using as little as 20 kWh/m3.

Save your resources

With ZLD technology

Absorber

Our patented absorber removes waste in your process water by separating water vapour and non-water vapour. The pure water vapour continues in the process, while the waste is continuously led back for further evaporation.

Silencer

The mechanical defoamer, breaks foam bubbles in the heat exchange evaporator, thereby preventing chemicals from following the steam further during the process.

The solution

E-MVR is the most cost-effective, sustainable and reliable technology for industrial wastewater treatment. Our ZLD series is a plug-and-play solution, built with flexibility in mind. This means that the technology can be adjusted and adapted to treat a wide range of wastewaters.

The process at Envotherm always starts with us testing your wastewater in our laboratory and finding out what your wastewater contains, how it can best be treated and, if you have several different types of wastewater, how they can be mixed. This approach ensures that we can always deliver the best possible solution for you and your wastewater. You are therefore always assured of an effective solution when you choose Envotherm.

Our add-on technologies can be adapted to our systems in flexible ways, so you’re guaranteed a clean distillate, no matter how complex your wastewater. Combined with our modular solutions and our competent staff, this also means that your plant can be adapted and upgraded should your needs change. For example, if you need more capacity or if new chemicals in your production cause your wastewater to foam.

Our unique technology gives you all the advantages you need to optimise the treatment of your wastewater and start benefiting from the advantages that technological developments can give you.

At Envotherm we give you a guarantee on the purity of your distillate, your energy consumption and on the annual capacity of our systems.